US Air Force Extends Development of Aircraft Repair Tents

Aerospace firm Cornerstone Research Group has secured a $1-million contract to extend maintainer-fabricated enclosure kit (MFEK) development for the US Air Force.

MFEKs are walk-in enclosures similar to pop-up tents used by sustainment teams when repairing parked fighter jets.

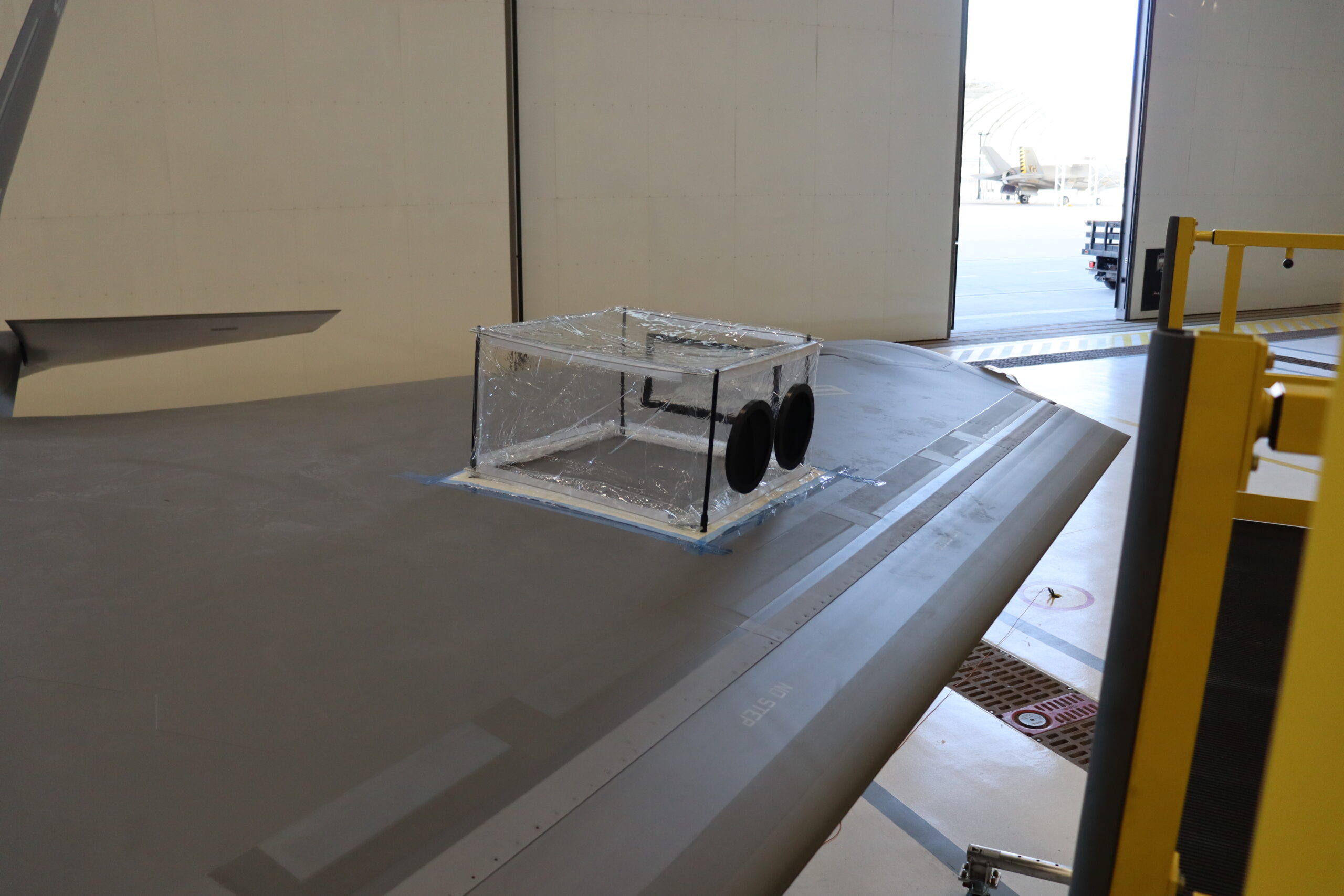

The air force wrote that the solution being designed, produced, and tested for the MFEK initiative is Cornerstone’s proprietary Deployable Isolation Repair Technology or DIRT Bag (DB) 6090.

The DB-6090 measures 60 x 90 x 60 inches, incorporates transparent panels and lightweight telescoping pole frames, and can be modified into other shapes and sizes.

This portable system keeps aircraft components, debris, and residual materials in an area segregated from the rest of the hangar or depot. It is compatible with temperature regulators to meet the environmental requirements of an aircraft part being repaired.

The DB-6090 can be transported via a 1’ x 1’ x 6’ rolling storage bag, removed, and deployed in less than 30 minutes.

The Ohio-based company signed the initial contract in February 2022. The latest award continues the framework agreement until June 2024.

Less Down Time

Cornerstone Project Lead Josh Adkinssetty highlighted the importance of MFEK when working on the F-35 Lightning II and its weapon systems, which the Air Force describes as a “challenging aircraft to maintain.”

“If it’s cold outside… maintainers have to pull it into the hangar [to maintain it], and that might mean needing to play musical aircraft, because at any given time they have all of these other aircraft that they know need worked on.”

“So, how do you manage all of that? This piece of gear [the DB-6090] kind of takes that out of the equation. I can go set this thing up on the flight line, throw a heater on it, control my environment, and perform the work that I need to, and it reduces the mean downtime between flights.”

The MFEK Project

Cornerstone is collaborating with US Air Force innovation arm AFWERX to demonstrate the DB-6090 to industry partners and program offices for future use.

The tent will eventually be made commercially available simultaneously with the approval of the system’s utility for US Department of Defense applications. Once on the market, the DB-6090 will be offered with DB-2424, a smaller DIRT Bag variant developed in the earlier MFEK phases.

Meanwhile, DB-6090 prototypes have completed field evaluations in military testing sites across California, Arizona, and other states for the solution’s introduction into service.